3 4 5 METHOD USED IN SETTING OUT

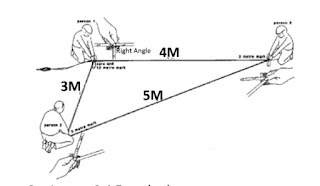

3 4 5 METHOD USED IN SETTING OUT The 3 4 5 method is an accurate method use in Ge tting the Exact Square of a Plan instead of Using the Engineering Square which may not be accurate for a Longer Span. The 3 4 5 method is an application of the Pythagoras Theorem. i.e Forming right Angle. Most times, 2 or 3 people are involved in this. 3 meters is Measure from the Parallel Line created, then 4 Meter Away from the First point forming a Right Angle, you use your Measuring tape to Confirm the distance between the 3m point noted at the parallel line and the 4m noted at the other line is 5m. Note that your Parallel line remains The same, you only shift the other line to form the right Angle.