Crank Bar in slab

Crank Bar in slab

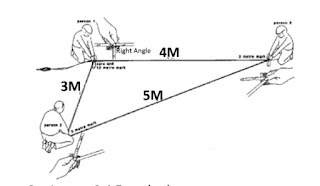

The slab is supported at two ends. The maximum tensile stress that is positive moments (sagging) acting in the middle of the slab and the maximum compressive stress that is negative moments (hogging) acting at both ends of the support. So bottom steel is required at the mid-span and top steel resists negative moments at the supports. A bent-up bar called a crank bar is provided to make RCC slab safe from compressive stresses.

Comments

Post a Comment