My site exposure

My site exposure

Recently I had an opportunity to visit the site at Maradu Ernakulam on 25th July 2019, during my training period of DCM in Civil Talents.com. This academy is working as a project consultancy for this site. Er. Sureshlal was guiding us and giving instructions. The Project Manager of this site is Mr.Vasanth Bhat and the site supervisor is Mr. Libin Anto.

The project site is a G +2 storied building of 6000sqft. On that day, the site was filled with water because of raining. The works on-site was dewatering, pile chipping. Pile chipping is required to remove the pile portion mixed with slurry and mud during concreting.

Chipping of piles

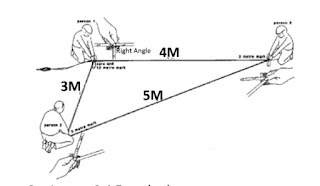

Our guide was giving instructions for measuring the height required for pile chipping using a dumpy level instrument.

Taking measurements for pile chipping

Due to heavy rains externals works such as excavation of plinth beam, pile chipping, were stopped temporarily and reinforcement works for pile caps and plinth beam was carried out during those days.

Reinforcement of pile cap - 2PC1

Usually, in the morning time, we were having theory classes about quantity surveying, billing, vasathu, MSP, etc at Marine drive. This class helped me to achieve more guidance for quantitative analysis of the site and also for billing.

Morning section at our lecture hall

Site meetings were conducted every Friday to review the progress of work and suggestions are taken to flow scheduled dates so, corrections are made accordingly.

After reinforcement work completion, blockwork was in progress. Blocks were provided over the sides of the pile cap up to half-length of the pile cap, because of site condition it was difficult to provide shuttering.

Blockwork provided on sides of the pile caps

Then excavation for the plinth beam was done then PCC was placed over it. After that placing of reinforcement for plinth beam, columns and for side walls were done day by day.

PCC provided

Reinforcement fixed for beam and column

Then shuttering work was done using timber and steel board.

Shuttering for plinth beam and pile cap

Then concreting was done by two phases. Concreting mix used for the pile cap and plinth beam is M20. Three cubes of 150x150x150mm were cast for testing its strength. During concreting, the vibration was done at each interval of 30cm to remove air bubbles.

|

| concreting |

|

| Level checking for concrete. |

|

| Cube casted for testing |

Comments

Post a Comment